The following Tuesday found the management team gathered in Emma’s conference room, this time with a noticeably different energy. Emma had made it clear: finding what comes after the whiteboard was now their top priority. No more fire drills would derail this conversation.

Sarah arrived with her laptop and a notebook full of ideas she’d been collecting. Over the past week, since Emma’s declaration that they’d “fix this properly,” she’d been thinking about solutions. And everywhere she looked—in her LinkedIn feed, in manufacturing newsletters, in conversations with other production scheduling managers—one word kept appearing: AI.

“Before we dive into scheduling software options,” Emma said as everyone settled in, “I want us to think about the bigger picture. We’ve had some remarkable successes with AI recently, and I think it’s worth exploring whether AI scheduling software could solve our challenges.”

Klaus leaned forward with interest. “You’re thinking about the website content project?”

Emma nodded. “Exactly. Three months ago, we were paying a marketing consultant €200 per product description. Now, with AI, we generate professional copy in minutes. The quality is good enough that we barely need to edit it.”

Patrick pulled up a document on the screen. “And the meeting transcripts have been a game-changer. Copilot automatically generates summaries, assigns action items, and even identifies follow-up tasks. We’re saving at least five hours a week just in meeting administration.”

Sarah found herself nodding. She’d been skeptical when Patrick first proposed using AI for meeting notes, but the results had been impressive. No more frantic scribbling during discussions, no more confusion about who was supposed to do what. The AI captured everything and organized it beautifully.

“The customer feedback analysis has been helpful too,” Jenny added from her seat near the door. “Instead of reading through hundreds of survey responses, the AI summarizes the key themes and sentiment. It’s like having an extra analyst on the team.”

Emma smiled. “So we’ve proven that AI can handle content generation, meeting documentation, and data analysis. The question is: can AI handle production scheduling?”

The AI investigation

Sarah opened her laptop. “I’ve been researching this. There are several AI scheduling tools on the market. They promise to use machine learning to optimize production schedules, predict bottlenecks, and adapt to changing conditions.”

She pulled up a demo video from one of the vendors. The interface looked sleek and modern, with colorful visualizations and confident predictions about optimal scheduling. The AI claimed it could analyze thousands of scheduling scenarios in seconds, learning from historical data to make increasingly accurate predictions.

“This looks promising,” Klaus said. “If AI can write marketing copy and summarize meetings, surely it can figure out how to schedule our jobs.”

Patrick was already pulling up technical specifications on his laptop. “The underlying technology is impressive. These systems use neural networks trained on manufacturing data. They can identify patterns that humans might miss. They also have an LLM, which means that their AI scheduling software speaks our language.”

“Let me show you another one,” Sarah said, switching to a different vendor’s website. This system promised even more: real-time optimization, predictive maintenance integration, and automatic rescheduling based on shop floor events.

Emma studied the screen thoughtfully. “Patrick, what would it take to test one of these systems?”

“Most vendors offer free trials,” Patrick replied. “We could set up a pilot within a couple of weeks. The main challenge would be getting our data into their format.”

The data reality check

Sarah felt a knot forming in her stomach. “That’s actually where I see the first problem. To properly test these AI scheduling systems, we’d need to feed them our actual production data. And our data…” She trailed off, thinking about the state of their information.

“What about our data?” Emma asked.

Sarah pulled up a Business Central report showing their routing times. “Look at this. Our estimated runtime for the bearing housing operation is fifteen minutes. But if you talk to Otto, he’ll tell you it varies between eight and forty-five minutes depending on the previous job, which operator is running it, and what tooling is already mounted.”

She scrolled to another report. “Here’s our shop calendar for machine five. According to this, it’s available twenty-four seven. But in reality, it’s down for maintenance every second Tuesday, and Werner won’t run certain jobs on it because the tolerances drift after long production runs.”

Klaus frowned. “Are you saying our master data is wrong?”

“I’m saying our master data reflects rough estimates and ideal conditions,” Sarah replied.

“Which is fine for financial planning and material requirements. But for AI to optimize our schedule, it needs either accurate and stable planning data or a comprehensive database with valid actual data from the shop floor. And we have neither one nor the other.

Our planning data is too fuzzy, as we just discussed. And with us just posting the finished production order, we do everything that Business Central needs to keep the inventory under control. However, we do not yet take the effort to post real dates and times for each operation on the shop floor.”

Patrick was quiet for a moment, then nodded slowly. “She’s right. I’ve been looking at our data quality metrics. Our routing times are estimates that haven’t been updated in years. We even copied and pasted them from our old system when we implemented Business Central. Our BOMs include operations that are sometimes done internally, sometimes outsourced, with no systematic way to track which approach we actually use. And our material lead times are based on supplier promises from two years ago, not current reality.”

Why AI scheduling requires better data

“But couldn’t the AI scheduling software learn from our actual performance?” Klaus asked. “If we feed it shop floor data over time, wouldn’t it figure out the real runtimes and build more accurate predictions?”

Sarah had asked herself the same question. “I thought about that. But here’s the challenge: to train an AI effectively, you need consistent, high-quality data over an extended period. We’d need to track actual start times, finish times, operator assignments, material availability, quality issues, and rework for every operation on every job for months, maybe years.”

She pulled up a spreadsheet she’d created over the weekend. “When trying to solve the puzzle over the weekend, I mapped out what we’d need to collect to make that puzzle work. It’s not just runtime data. And as we would need more data, the AI would need the same information. The AI would need to understand why times vary—which operator was assigned, what the previous setup was, whether we had all materials on hand, if there were quality holds, and how many interruptions occurred. Without that context, the AI would just be learning from noise.”

“And we don’t collect any of that data currently,” Patrick said quietly.

“Exactly. We post output and consumptions when jobs are finished, but we don’t track shop-floor progress in real time. We don’t systematically record why some operations take longer than others. We don’t log interruptions or material shortages or quality issues in a structured way. Likewise, we do not track machine outages.”

Emma leaned back in her chair. “So before we could even try AI-based scheduling, we’d need to implement much better data collection on the shop floor?”

“That’s what it looks like,” Sarah confirmed. “And even then, we’d need several months of clean data before the AI could learn meaningful patterns. During that time, we’d still be scheduling with the whiteboard.”

The fundamental difference

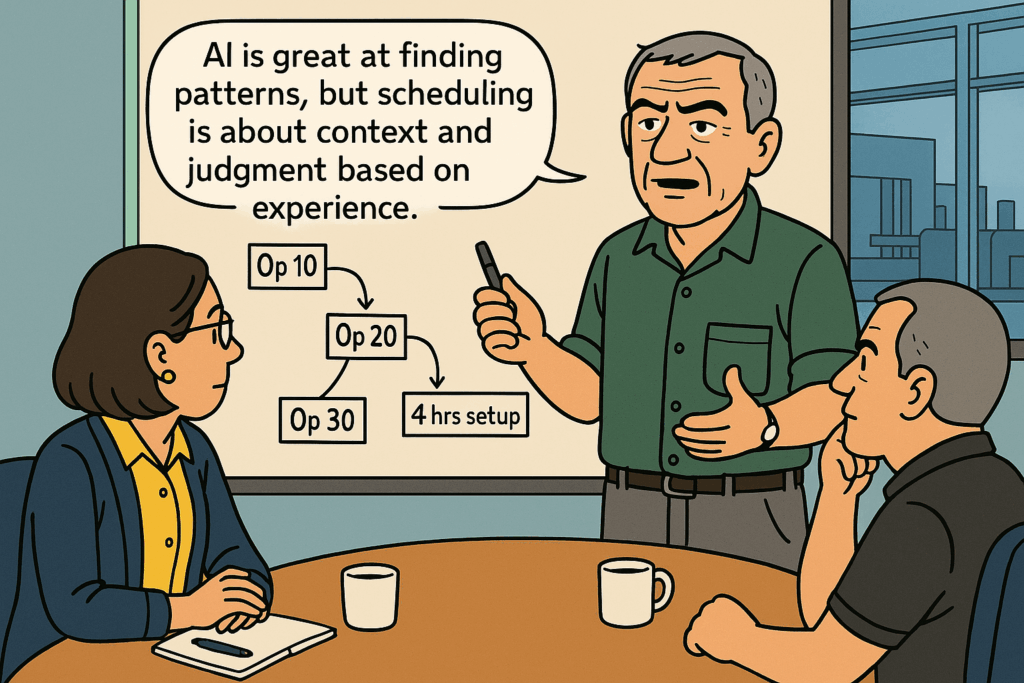

Otto, who had been quietly listening from the back of the room, finally spoke up. “Can I say something about this AI business?”

“Please,” Emma gestured for him to continue.

Otto stood and walked to the whiteboard at the front of the room. “I’ve been listening to all this talk about AI, and it reminds me of when we first got Business Central. Everyone was excited because the computer could do calculations faster than humans. And that’s true—it can add numbers and track inventory better than I ever could.”

He drew a simple diagram on the whiteboard—a production order with several operations. “But here’s what I don’t understand about using AI for scheduling. When I’m on the shop floor and Hans tells me machine seven is making a funny noise, I know to move that critical job to machine three even though it means a longer setup. I know that because I’ve seen machine seven fail before, and I know what it costs us when it goes down mid-job.”

He added another note to the diagram. “When Müller tells me he’s not feeling well, I know not to put him on the precision boring operation because that requires perfect concentration. I know that because I’ve worked with Müller for twelve years, and I know when he’s at his best and when he’s not.”

Otto turned back to the group. “Now, maybe AI could learn these things eventually. But how long would it take? How many failures would we have to have before the AI figured out that machine seven’s funny noise means trouble? How many bad parts would we produce before it learned that a tired operator shouldn’t run precision work?”

The room was quiet. Sarah found herself nodding—Otto had articulated something she’d been struggling to put into words.

“AI is great at finding patterns in data,” Otto continued. “But scheduling isn’t just about patterns. It’s about understanding context, reading situations, and making judgment calls based on experience. How do you train an AI to know that Klaus’s tone of voice on a customer call means we need to prioritize that order, even if it’s not technically the most urgent?”

Sarah’s weekend revelation

Sarah cleared her throat. “Otto’s point connects to something I realized last weekend when I was trying to rebuild the schedule. The problem wasn’t that I couldn’t calculate the optimal sequence—given enough time, I probably could have figured it out heuristically. The problem was that I couldn’t see all the dependencies and conflicts simultaneously.”

She stood and joined Otto at the whiteboard. “Miguel asked me why I was working like it’s 1985, and he was right to ask. But the answer now isn’t necessarily AI. The answer is visibility and tools that help me manage complexity without requiring perfect data or months, if not years, of training time.”

She drew her own diagram—a simplified version of the cascade effects she’d struggled with. “What I needed last weekend wasn’t an AI to tell me the optimal schedule. I needed a way to see what happens when I move the Agrar-Tech job to machine three. I needed to instantly understand how that change affects the Kemper order, which affects the Steinbach components, which affects the operator schedules.”

“Like a simulator,” Patrick said thoughtfully.

“Exactly. Not artificial intelligence, but amplified intelligence. A tool that makes it easy for me to test different scenarios and see the consequences immediately. A tool that shows me the conflicts and constraints in real-time so I can make informed decisions.”

AI scheduling vs. pragmatic scheduling software

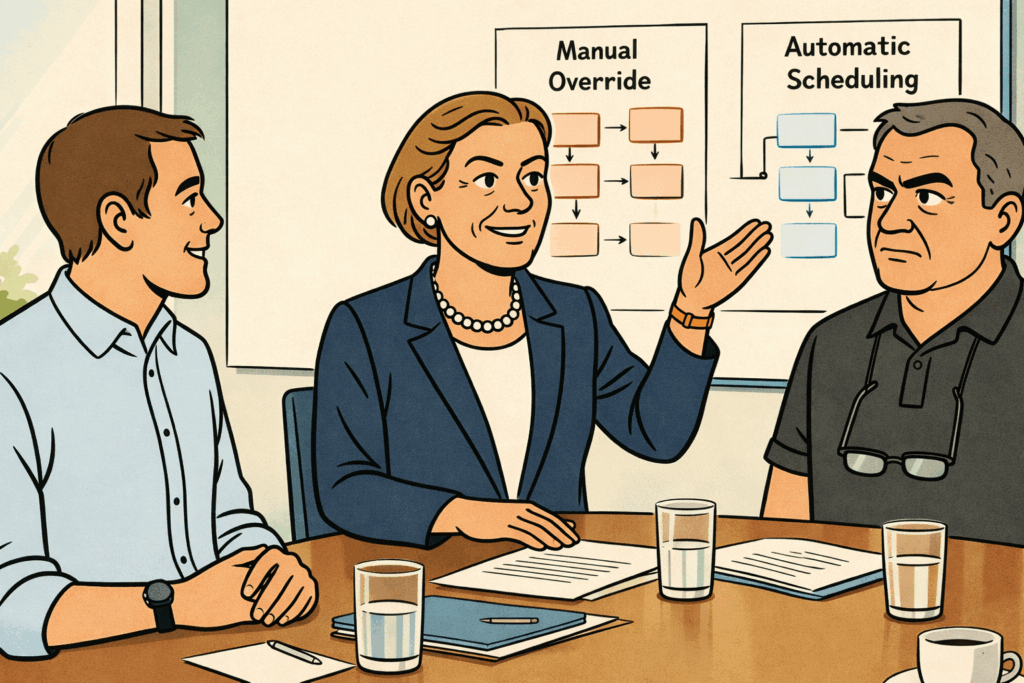

Emma studied the whiteboard where Sarah and Otto had been sketching their ideas. “So you’re suggesting we shouldn’t pursue AI-based scheduling?”

“I’m suggesting we need to walk before we run,” Sarah replied. “AI is powerful for pattern recognition and content generation—we’ve proven that with our other projects. But as of now, production scheduling in our environment requires something different. It requires understanding physical constraints, human factors, and business context that aren’t easily captured in data.”

“And it requires data quality we don’t currently have,” Patrick added. “Even if we wanted to use AI, we’d need to build the foundation first—better data collection, systematic tracking, consistent master data. That’s months of work before we could even start training an AI system.”

Klaus spoke up. “What about using AI as one component? Maybe not for the whole scheduling problem, but for specific parts?”

Sarah considered this. “That might make sense down the road. AI could potentially help with demand forecasting, or predicting when machines need maintenance, or identifying patterns in quality issues. But for the core scheduling challenge—figuring out what to make when with the resources we have—I think we need something more practical and immediate.”

Emma looked around the table. “Patrick, you said earlier that most AI vendors offer free trials. Should we at least test one to see if we’re being too pessimistic?”

Patrick shook his head. “Actually, I’m with Sarah on this. I’ve been looking at the data requirements while we’ve been talking. These AI systems need clean, structured input to produce reliable output. Garbage in, garbage out. And right now, our data isn’t ready for AI-level analysis.”

“Plus,” Sarah added, “we need a solution now, not in six months after we’ve cleaned up our data and trained an AI model. Emma, you said last Monday that we can’t afford another quarter like the last one. We need something that works with our current data quality and provides immediate improvement.”

The path forward

Emma stood and walked to the window overlooking the shop floor, where the familiar scene of organized manufacturing continued. “Alright. I hear what you’re saying. AI has been valuable for content and analysis, but production scheduling is a different beast. We need something more practical.”

She turned back to face the group. “Sarah, what do you recommend as our next step?”

Sarah took a deep breath. This was the moment she’d been building toward. “I think we need to look at dedicated production scheduling software. Not AI-based systems that promise to optimize everything automatically, but practical tools designed specifically for finite capacity scheduling in high-mix, low-volume environments like ours.”

“What’s the difference?” Klaus asked.

“The difference is in the approach,” Sarah explained. “AI systems try to find the optimal solution by analyzing massive amounts of data and learning patterns. Scheduling software provides visibility and tools to help humans make good decisions based on their expertise and judgment. It doesn’t try to replace our knowledge—it amplifies it.”

Otto nodded approvingly. “That makes more sense to me. I don’t need a computer to tell me the perfect schedule. I need a computer that shows me what’s happening and helps me see the consequences of my decisions.”

Patrick was making notes on his laptop. “So, we’re talking about finite scheduling software with visual interfaces, drag-and-drop capabilities, and real-time conflict detection?”

“Exactly,” Sarah confirmed. “Software that helps me do what I was trying to do last weekend—test different scheduling scenarios and see the impacts immediately. Software that works with our current data quality while helping us improve it over time.”

Emma smiled. “This feels like we’re getting somewhere. Sarah, I want you to research scheduling software options. Not AI systems, but practical scheduling tools. Bring back recommendations for what we should evaluate.”

“I can do that,” Sarah said, relief flooding through her. They weren’t abandoning the search for solutions—they were just being realistic about what kind of solution would actually work for Alpine.

“One more thing,” Patrick added. “I want to bring in outside expertise. Marcus Müller from our Business Central implementation partner firm has been working with other manufacturing clients before. Let’s get his perspective on how scheduling software could integrate with our existing systems.”

Klaus raised his hand. “And maybe someone who specializes in production scheduling? Marcus is great with Business Central, but scheduling is its own discipline.”

“Good idea,” Emma agreed. “Patrick, when you speak to Marcus, address this openly. Ask him whether he is confident he can help us succeed with scheduling on his own, or if he would prefer to add a subject-matter expert to the team. Maybe he knows someone who is a pro with both scheduling and Business Central? Someone who can help us understand what’s realistic and what’s not?”

Patrick made a note. “Noted down already. Will call him right away.”

A lesson learned

As the meeting wrapped up, Sarah gathered her materials and felt a mixture of relief and determination. They’d almost fallen into the trap of chasing the latest technology without understanding whether it actually solved their problem. AI was powerful, but it wasn’t a magic solution for every challenge.

Her phone buzzed with a text from Miguel: “Tom’s coach wants parent volunteers for Saturday’s tournament. You available?”

Sarah looked at the message, then at Emma, who was talking with Otto near the door. For the first time in weeks, she felt like they had a real path forward. Not a perfect path, not a magical AI solution, but a practical approach that acknowledged their current reality while working toward improvement.

“Definitely available,” she typed back. “Wouldn’t miss it.”

As she walked back to her office, she thought about the irony of the morning’s discussion. They’d started by talking about how AI could solve their scheduling problems and ended by realizing that what they really needed was better tools to leverage human expertise, not replace it.

Sometimes the most advanced solution wasn’t the most sophisticated technology. Sometimes it was simply finding the right tool for the specific job, with realistic expectations about data, capabilities, and timelines.

The question now was: what were the right scheduling tools, and how would they integrate with Alpine’s existing systems? That conversation, she suspected, would be even more complex than the AI scheduling discussion. But at least now they were asking the right questions.