By Friday afternoon, Sarah realized that the urgent had once again trumped the important. The management team’s Tuesday discussion about “what comes after the whiteboard” had been completely sidelined by the week’s fire drills. Wednesday had been consumed with getting CNC machine Mazak #3 back online for the Brenner Industries order. Thursday had vanished into coordinating the delayed heat treatment delivery and managing the ripple effects across three different customers. Now, standing before her whiteboard on Friday afternoon, she could see they’d managed to get everything back on track through sheer force of will and overtime hours.

The irony wasn’t lost on her. They’d identified a fundamental problem with their manual scheduling approach, acknowledged that their systems weren’t adequate for their growing complexity, and then immediately reverted to those same inadequate systems because there were customers to serve and deliveries to make. It was the classic trap of small manufacturing companies—too busy bailing water to fix the leak in the boat.

The colored magnetic strips on her whiteboard told a story of successful crisis management. The Brenner order was shipping on time. The agricultural components had made it through final assembly. Even the mysterious Steinbach materials had been processed and were ready for delivery. For once, everything looked under control.

She was actually contemplating leaving early—maybe surprising Tom at his after-school program, grabbing dinner as a family for the first time all week—when her phone rang at 4:47 PM on Friday.

The perfect storm begins

“Sarah, it’s Frank Werner from Agrar-Tech,” came the voice that immediately made her stomach clench. “I’m sorry to call so late on Friday, but we’ve got an emergency. Our customer has just experienced a major equipment failure, and they need to reschedule their planting operation entirely. We need our order delivered next Friday instead of two weeks from now.”

Sarah stared at the whiteboard, specifically at the neat schedule she’d constructed for the following week. The Agrar-Tech order was a complex job requiring multiple operations across different departments, currently planned for the third week of the month. Moving it up by an entire week wasn’t just rearranging priorities—it would require completely rebuilding the schedule.

“Frank, that’s going to be very challenging,” she began.

“I know it is, and I’m sorry. However, if we can’t deliver next Friday, they will source the components elsewhere. We’re talking about losing a €120,000 order that could turn into regular business.”

“OK. I need to see how to change the schedule. I will do this over the weekend and confirm with the team here on Monday, first thing in the morning. Then I will call you back, latest by Monday at 09:00 AM.“

You are a star, Sarah. Thank you very much and have a lovely weekend – despite the extra challenge that I just gave you.”

Before she could even begin calculating the implications, her office phone rang. Jenny’s extension.

“Sarah, I’ve got bad news from our steel supplier. That special alloy shipment for the Hoffmann precision components? The mill had quality issues. Delivery is pushed back from Monday to Wednesday, maybe Thursday.”

Sarah felt her carefully constructed schedule beginning to crumble. The Hoffmann components were scheduled to start production on Monday, feeding into a tight sequence of operations that would barely meet their customer’s delivery requirements. A three-day delay in materials would push everything back, creating conflicts with jobs already scheduled for later in the week.

“How confident are they about Wednesday?” she asked.”About as confident as they were about Monday,” Jenny replied with characteristic sarcasm.

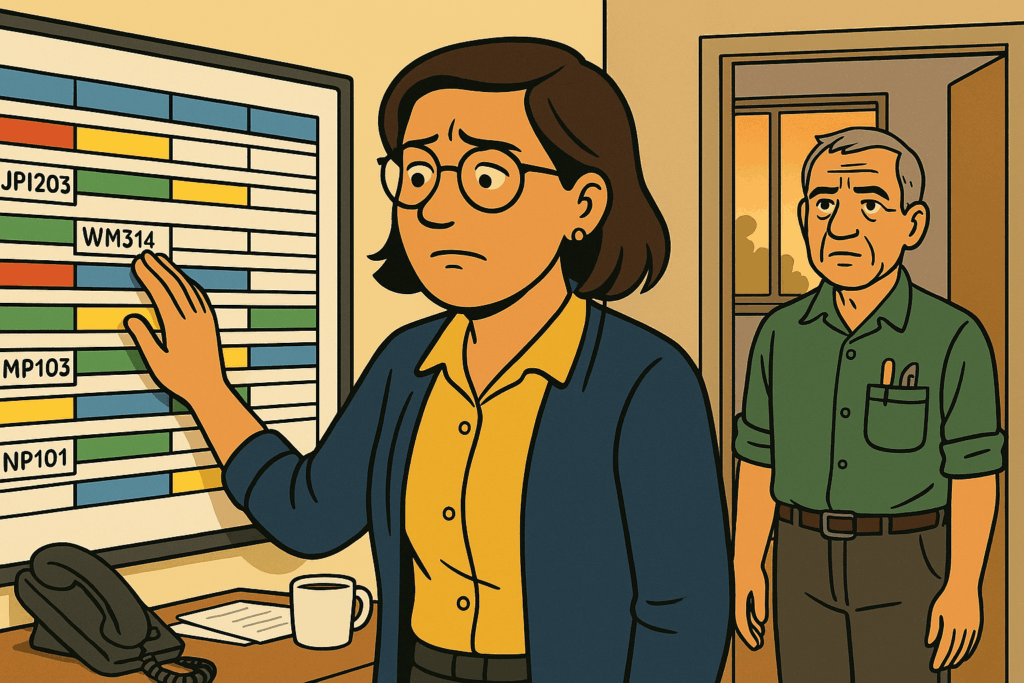

As Sarah was processing this new complication, Otto appeared in her doorway with the expression of someone bearing news that would make her start into the weekend even more complicated.

“CNC Machine five,” he said without preamble. “The main spindle bearing is making noises that sound like a dying whale. Hans thinks we need to shut it down before it damages the entire machine.”

Sarah looked at her whiteboard, where the machine was scheduled for critical operations on three different orders next week, including the Agrar-Tech job that now needed to be expedited. “How long to fix it?”

“If we can get parts over the weekend, maybe Tuesday. More likely Wednesday or Thursday.”

The room went quiet as the full implications sank in. A key customer demanding an expedited delivery, critical materials delayed by at least three days, and one of their most important machines going offline for potentially a week. Sarah stared at her whiteboard, where the neat rows of colored magnetic strips suddenly looked like dominoes waiting to fall.

“I need to think about this,” she said finally. “Let me work on it over the weekend and see what I can figure out.”

After Otto left, Sarah gathered her things and headed home, her mind already churning through scheduling scenarios. She’d dealt with individual crises before, but the combination of expedited orders, delayed materials, and equipment failures created a puzzle of unprecedented complexity.

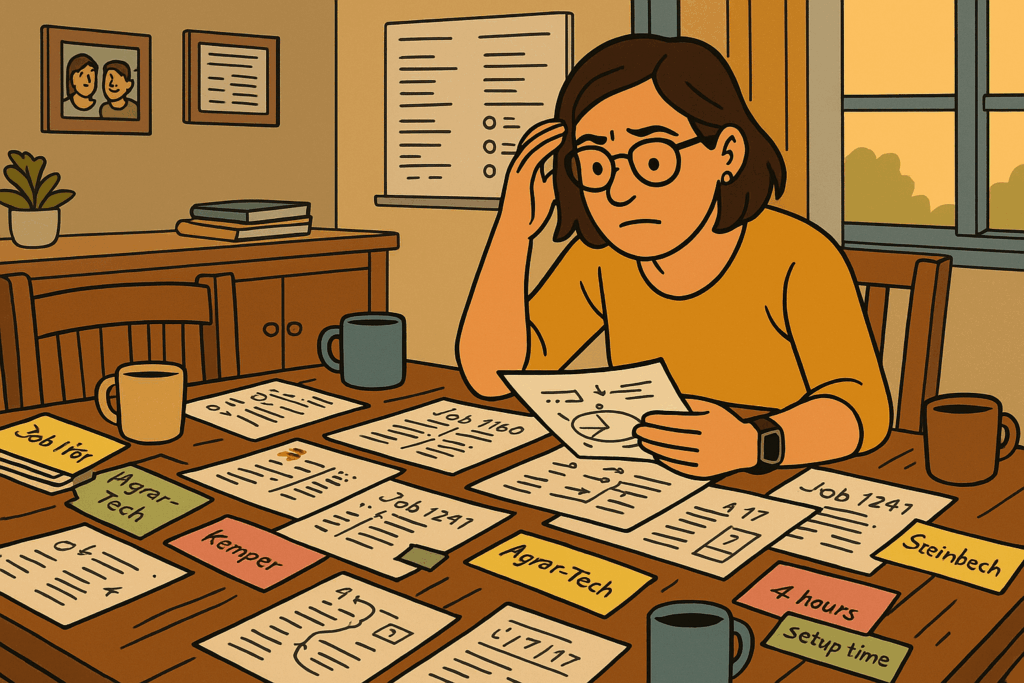

The weekend marathon of manual scheduling

Saturday morning found her at the kitchen table at 6 AM, surrounded by printed production orders, routing sheets, and pages of hand-scrawled notes. She’d converted her dining room into a command center, with multiple whiteboards propped against the walls and sticky notes covering every available surface. Miguel had quietly provided coffee and breakfast, recognizing the focused intensity that meant she was wrestling with a particularly stubborn manual scheduling problem.

She started by mapping out the Agrar-Tech expedited order, tracing its path through each operation and identifying the resources it would need. Then she attempted to compress the timeline, looking for operations that could be parallelized or setup times that could be minimized. The math was unforgiving—even working at maximum efficiency, the job required more time than they had available.

By Sunday afternoon, she’d filled seventeen pages with scheduling calculations and other notes, trying to find a way to fit the expedited order into next week’s capacity while accommodating the delayed materials and the offline machine. Each attempt revealed new conflicts. Expediting one job created bottlenecks that delayed others. Rearranging machine assignments created setup inefficiencies that ate up the time she’d saved. Working overtime could solve some of the new bottlenecks, but not all of them. Especially as some of the operations required special skills from employees that they couldn’t simply “clone”. Also, having the EBIT issue in mind, Sarah tried to keep overtime as low as possible to avoid significant cost increases.

The cascade effect

The cascade effects were impossible to track manually. Moving the Agrar-Tech job to Mazak #3 meant displacing the Kemper Industries order, which could only run on Mazak #3 or #7. But Mazak #7 was scheduled for the Steinbach components, which used specialized tooling that took four hours to set up. Moving Steinbach to a different day created conflicts with the operator schedules, since Hans Klein was the only one certified on that particular process.

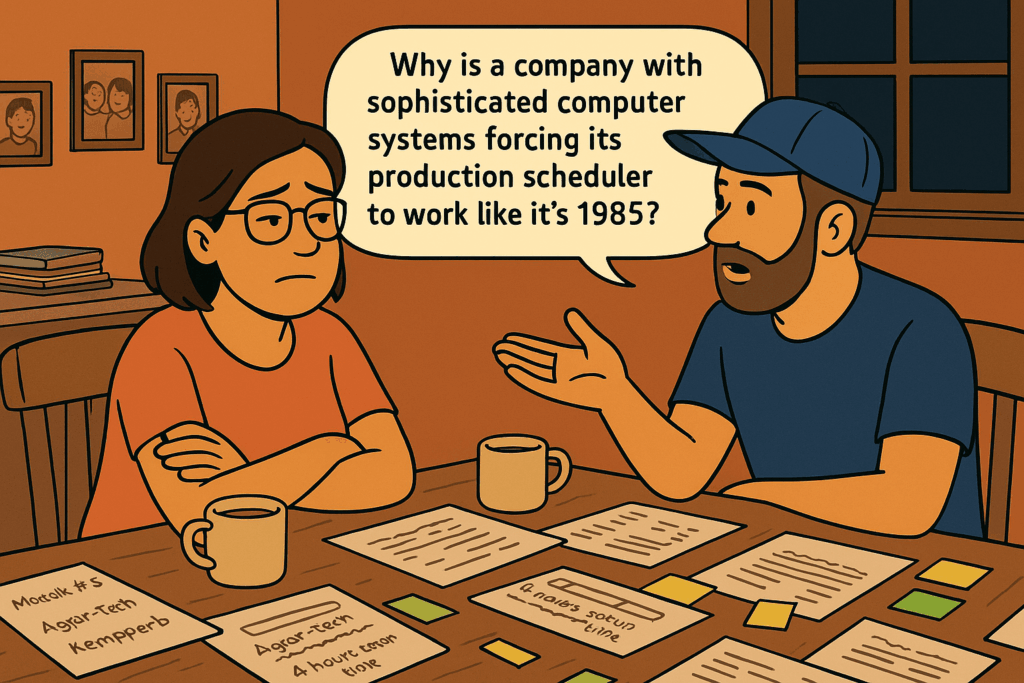

Sunday evening found her still at the kitchen table, pages of calculations spread before her like battle plans, when Miguel appeared with a cup of tea.

“You know,” he said gently, sitting down across from her, “I work with computer systems all day that can model complex scenarios, run simulations, and optimize multiple variables simultaneously. I’m watching you try to do the same thing in your head with a pencil, a paper, and a magnetic board, and I have to ask—why is a company with sophisticated computer systems forcing its production scheduler to work like it’s 1985?”

Why Manual Scheduling Fails at Scale

Sarah looked up from her notes, seeing her husband’s concerned face across a table covered with the physical evidence of Alpine’s scheduling complexity. Around them, Tom’s homework was stacked neatly on the counter, weekend plans had been abandoned, and family time had been sacrificed to the demands of magnetic strips and routing sheets.

“Because the sophisticated computer systems don’t understand finite capacity,” she said wearily. “Business Central can tell me what needs to be made and when, but it can’t tell me how to actually make it happen with the machines and people we have.”

“And the whiteboard?”

Sarah gestured at her improvised command center, with its multiple boards and countless notes. “The whiteboard can’t handle this level of complexity. I’ve been moving pieces around for two days, and every solution creates new problems I can’t see until it’s too late.”

Miguel looked around the dining room that had been transformed into a manual scheduling laboratory. “Sarah, you’re one person trying to mentally simulate the interactions of dozens of jobs across multiple machines with hundreds of individual constraints. Even the smartest person in the world couldn’t track all these interdependencies manually.”

She followed his gaze, seeing their home invaded by the complexity she couldn’t contain at work. It was a physical manifestation of the impossible burden she’d been carrying—trying to be the human interface between Business Central’s infinite capacity assumptions and the finite reality of their manufacturing operations.

“I know,” she said quietly. “But I don’t know what else to do.”

Monday morning reality

By Monday morning, Sarah had developed what she hoped was a workable solution, though it required overtime shifts, rearranged material deliveries, and several compromises that left her feeling less than confident. She arrived at the office at 6:30 AM, an hour before anyone else, to update the whiteboard with her weekend’s calculations.

As she moved the magnetic strips into their new positions, she began to see problems she hadn’t anticipated. The expedited Agrar-Tech order would indeed fit into next week’s schedule, but only by pushing the Hoffmann components into the following week, which created conflicts with orders she hadn’t even considered.

By 8 AM, she was staring at a whiteboard that looked like a child’s puzzle with pieces that didn’t quite fit together. Each adjustment revealed new gaps, new conflicts, new impossibilities she hadn’t seen in her weekend calculations.

Emma’s decision

Emma arrived at 8:15, earlier than her usual schedule, and found Sarah standing motionless before the whiteboard with the expression of someone who’d just watched their house of cards collapse.

“Rough weekend?” Emma asked gently.

Sarah gestured at the whiteboard, where colored strips were arranged in patterns that made sense individually but created chaos collectively. “I spent two days rebuilding the schedule to handle the Agrar-Tech expedite, the delayed materials, and machine five being down. I thought I’d figured it out, but now that I see it all together…”

She trailed off, unable to articulate the depth of her frustration. The weekend’s work, including all the calculations, rearrangements, and careful optimizations, had produced a schedule that was theoretically possible but practically unworkable.

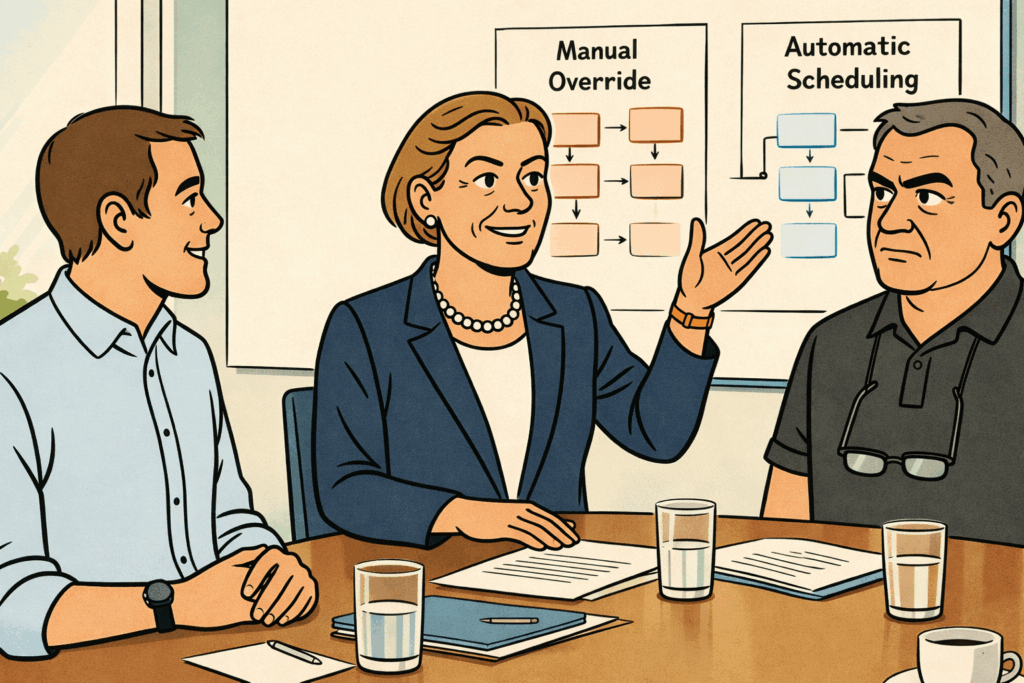

Emma studied the whiteboard, taking in the complexity of intersecting constraints that Sarah had tried to balance. “You know what this reminds me of?” she said after a long moment. “It reminds me of the early days when we were trying to manage everything in spreadsheets. We kept adding more columns and more formulas until the spreadsheets became so complex that no one could understand them anymore. That’s when we realized we needed proper business software.”

Sarah looked at her whiteboard with new eyes, seeing it not as a sophisticated scheduling tool but as an elaborate spreadsheet made of magnetic strips and dry-erase markers.

“Sarah,” Emma said quietly, “we’re going to fix this properly. No more band-aids. No more heroic weekend efforts. No more asking you to perform miracles with tools that weren’t designed for the job we’re asking them to do.”

Sarah felt something release in her chest—relief, hope, and exhaustion all mixed together. For months, she’d been carrying the burden of Alpine’s scheduling complexity on her shoulders, trying to bridge the gap between what their systems could do and what their business required. Now, finally, someone was acknowledging that the gap had grown too wide for any individual to span.

“What do you mean?” she asked.

Emma looked around Sarah’s office, taking in the whiteboard that had served them for years but was now clearly overwhelmed by the complexity it was asked to manage.

“I mean, it’s time to figure out what comes after the whiteboard,” Emma said. “And this time, we’re not going to let the urgent distract us from the important. This is officially our top priority.”