What came next? —This sudden inspiration caught Sarah. She closed her eyes and wanted to give it some thought. But this moment of silence came to a fast end.

Her phone buzzed sharply, interrupting her contemplation. Another text from Miguel, but this one carried a different tone: “Sarah, you said you’d ‘try your best’ to make Tom’s game. He needs you to BE there, not to try to be there. Please don’t make this another maybe.”

The words hit harder than any customer complaint. Miguel wasn’t asking for much—just for her to show up for their son the way she showed up for work every day. But lately, “showing up” for Tom had become another item on her impossible scheduling puzzle, competing with machine breakdowns and customer emergencies for her attention.

She thought about Tom, ten years old and still young enough to believe his mother could solve any problem, fix any crisis, be anywhere she promised to be. How long before he stopped believing that? How long before he stopped expecting her at his games because experience had taught him that work always won?

The irony stung. She spent her days trying to make sure Alpine delivered on its promises to customers, but she was failing to deliver on her promises to the most important customer in her life. Miguel was right—Tom didn’t need her to try. He needed her to decide, to commit, to make it happen.

The Morning Hunt Begins

She was reaching for her phone to text back a firm “I’ll be there” when Jenny burst through her doorway, clipboard in hand and the kind of harried expression that usually meant more bad news.

“I’ve been trying to track down the status of five different orders this morning,” Jenny announced without preamble. “And I’m starting to think some of them might have been abducted by aliens.”

Despite everything, Sarah almost smiled. Jenny’s dry humor was one of the things that kept the production office sane during weeks like this. “Which ones are playing hide and seek now?”

“Well, the Hoffmann precision couplings were supposed to be in final assembly in the extra shift we ran on Saturday but Mike says he never got them from quality control. Quality control says they sent them back to machining for rework on Friday, but Werner at the CNC stations says he hasn’t seen hide nor hair of them.” Jenny consulted her clipboard. “Then there’s the Weber drive shaft components—Otto thought they were in heat treatment, but we just found out that batch got delayed, so those parts are still sitting somewhere on the shop floor. Problem is, nobody can remember exactly where. We truly have a shop floor visibility issue.”

The Customer Complaint

Sarah’s phone rang before she could respond. She glanced at the caller ID and winced—it was Agrar-Tech, the agricultural equipment customer whose Thursday delivery had just evaporated thanks to the heat treatment delay.

“Sarah Martinez,” she answered, trying to inject confidence she didn’t feel into her voice.

“Ms. Martinez, this is Frank Hallberg from Agrar-Tech. I’m calling to confirm our Thursday delivery. Our production line is scheduled around those components arriving on time.”

Sarah looked at Jenny, who was mouthing “heat treatment Wednesday” while making apologetic gestures. “Mr. Hallberg, I’m afraid I need to discuss a slight adjustment to your schedule. We’ve encountered a delay with our heat treatment subcontractor—”

“How much of a delay are we talking about?” The edge in Hallberg’s voice was sharp enough to cut steel.

“The earliest we can ship would be Friday morning, which means Monday delivery to your facility.”

The silence on the other end of the line stretched long enough for Sarah to hear the background noise from the shop floor below—pneumatic tools, conveyor belts, and what sounded like someone calling out machine part numbers.

“Ms. Martinez,” Hallberg finally said, his voice carefully controlled, “this is the fourth time in three months we’ve had to adjust our production schedule because of delays from Alpine. We have loyal customers, but our loyalty has limits.”

The Search Intensifies

After the call ended—with promises to “discuss this internally” that didn’t sound promising—Sarah found herself staring at the whiteboard again. Somewhere in those neat rows of colored magnetic strips was the illusion that she knew where everything was and when it would be done. The reality playing out around her suggested otherwise.

“Jenny,” she said suddenly, “grab Mike and see if you can physically locate those Hoffmann couplings. I don’t care if you have to search every workstation, quality inspection booth, and storage area. We need to know where they are.”

“Already tried that,” Jenny replied. “Mike’s been looking for twenty minutes. He says it’s like playing Where’s Waldo, except Waldo is industrial precision components and the picture keeps changing.”

Sarah’s computer chimed with another email notification. This time the subject line read: “Production Status Inquiry – Kemper Industries.” She didn’t need to open it to know it was another customer wondering where their order was in the production pipeline.

The irony wasn’t lost on her. They had sophisticated ERP software that tracked every sales order, every purchase order, every warehouse receipt, every invoice and payment. Business Central could tell her the exact cost of materials for any job, generate precise financial reports, and automatically calculate their tax obligations. But ask it where production order #4521 was at this exact moment, or whether the components for the Steinbach job had been machined yet, and the system went silent.

“The problem,” she muttered to herself, “is that we can track every Euro, but we can’t neither track every part nor the execution progress of each shopfloor operation.”

Shop Floor Reality Check

Her phone buzzed again. This time it was Otto calling from the shop floor.

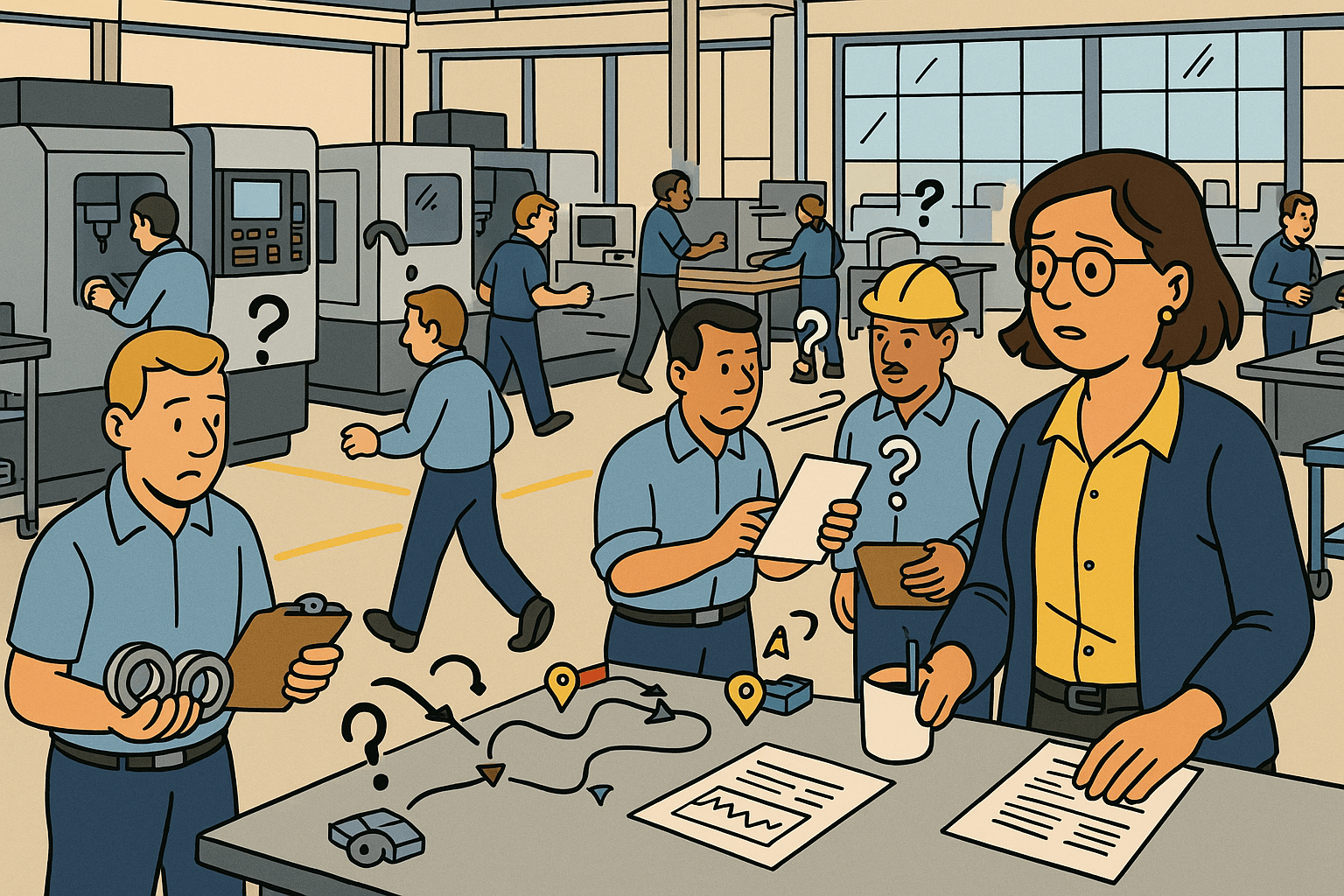

“Sarah, I’ve got Müller asking me where the material is for the Steinbach job. Jensen wants to know if the tooling for the bundled operations for the special agricultural components is available yet. And Schmidt just told me he finished the first operation on the Brenner housings, but he doesn’t know where they’re supposed to go next because the routing sheet got coffee spilled on it.”

Sarah closed her eyes and massaged her temples. Each question Otto was asking represented a worker standing idle, waiting for information that should have been readily available. Each minute of confusion was money walking out the door.

“I’ll be right down,” she told Otto.

The shop floor at 10:30 on Monday morning looked like controlled chaos, emphasis on the chaos part. Sarah walked through the maze of machines, workstations, and material carts, noting the subtle signs of inefficiency that wouldn’t show up on any report. Here, an operator stood looking around uncertainly, obviously searching for something. There, a small group had gathered around a routing sheet, studying it like archaeologists deciphering ancient hieroglyphics.

The Mystery of the Missing Parts

At workstation seven, she found Schmidt holding a precision bearing housing and looking thoroughly confused.

“These came off Mazak three before it went down,” he explained, showing her the parts. “The routing says they go to station twelve next, but station twelve says they’re not expecting them until Wednesday. Meanwhile, I’ve got machine time scheduled for the Kemper job, but I can’t find the materials for that anywhere.”

Sarah looked at the bearing housings—perfect examples of Alpine’s precision machining capabilities, worth several hundred euros each, and currently homeless because nobody could agree on where they belonged in the production sequence.

“Have you checked with quality control?” she asked.

“That’s where it gets interesting,” Schmidt replied. “QC says they already inspected a batch of bearing housings this morning, but they sent them to assembly. Assembly says they haven’t received any bearing housings today. So, either we’ve got bearing housings that have achieved invisibility, or somebody’s ‘database’ is lying to them.”

Twenty feet away, she spotted Weber—not the customer, but Hans Weber, one of their most experienced operators—walking purposefully between workstations with a determined expression that usually meant he was hunting for something specific.

“Hans!” she called out. “What are you looking for?”

“The tooling for the agricultural component,” he replied, not slowing down. “It was supposed to be returned from machine six Friday afternoon, but it’s not in the tool crib, it’s not at machine six, and the tool crib manager swears he never checked it back in.”

Sarah felt a familiar knot forming in her stomach. The tooling Weber was looking for was custom-designed for that specific job. If it was truly lost, they’d have to remake it, adding days to an already-delayed schedule—not to forget the extra cost that this would incur.

Klaus Calls With More Problems

Her phone rang again. Klaus’s number this time.

“Sarah, I just got a call from Steinbach Industries,” Klaus’s voice carried the particular strain that came with fielding customer complaints. “They want to know why their job isn’t in production yet. Apparently, they were told it would start this morning.”

Sarah looked around the shop floor, taking in the scene of organized confusion. Workers doing their best with incomplete information. Supervisors trying to coordinate activities without knowing where all the pieces were. Materials and parts scattered across workstations in various stages of completion, their progress invisible to anyone not physically standing next to them.

“Klaus,” she said, “I need to ask you something. When you run those Business Central reports showing our work in progress, what exactly are they measuring?”

“Standard stuff. Production orders released, materials consumed, hours reported. “

“When do we add this information into the system? I mean, the materials consumed, and the hours reported?”

“Once the entire production order is finished. Why?”

“Because I’m standing in the middle of our work in progress right now, and I can tell you that what’s actually happening bears no resemblance to what those reports probably say is happening.”

There was a pause on the other end. “What do you mean?”

“I mean, we have zero shop floor visibility. When it comes to many details, we just miss transparency.”

The Shop Floor Visibility Gap

Sarah walked over to a nearby workstation where parts for three different orders sat in various stages of completion. “I mean we’ve got parts scattered across the shop floor that aren’t showing up in anyone’s system. We’ve got operations that have been completed but not reported. We’ve got materials that have been consumed but not recorded. And we’ve got workers asking me questions that I can’t answer because the information they need doesn’t exist anywhere in any system.”

“Sarah—”

“Klaus, I’ve been thinking about what Otto said this morning. About how the whiteboard worked fine when we were smaller. The problem isn’t just that we’ve grown. The problem is that we’ve grown in a way that makes our production invisible to ourselves.”

She paused, watching a forklift operator navigate carefully around a cluster of material carts that probably shouldn’t have been parked there. Everything looked busy. Everything looked productive. But looks, she was beginning to realize, could be deceiving.

“When we had thirty people and twenty orders,” she continued, “everyone knew where everything was because they could see it all. Otto could walk the floor and tell you the status of every job from memory. Now we’ve got a hundred people and we’re lucky if we can tell you on which machine a particular job is.”

Her phone buzzed with a text from Miguel: “Tom’s coach wants to know if any parents can help with the cafeteria tonight. They want to make fresh waffles for the parents during the game, and then for the kids and team after the game. Nice initiative to build up the team spirit. Available?”

The Breaking Point

Sarah stared at the message, then at the shop floor around her, then back at the message. Her son’s team needed help with something tangible and manageable—parent’s support and helping the kids to become a real team. Meanwhile, she was drowning in a production environment where finding a set of precision parts apparently required the investigative skills of a detective.

“Klaus,” she said, “I think we need to have a serious conversation about how we’re managing production. Because this isn’t sustainable.”

“What kind of conversation?”

Sarah watched Otto appear at the far end of the shop floor, walking purposefully toward a machine where an operator was gesturing helplessly at a computer screen. Even from this distance, she could see the body language of someone trying to solve a problem with inadequate information.

“The kind where we admit that having great financial software doesn’t help us if we don’t know where our actual products are,” she said. “The kind where we acknowledge that we can’t manage what we can’t see. And the kind where we figure out how to make our production as visible as our accounting.”

There was another pause. “Are you saying our ERP system isn’t working?”

“I’m saying our ERP system is working exactly as designed—for tracking transactions, managing inventory, processing orders, generating invoices. But Klaus, production isn’t just transactions. It’s physical parts moving through physical processes, and somewhere between the computer screen and the shop floor, we’ve lost the ability to track what’s actually happening.”

Jenny’s Discovery

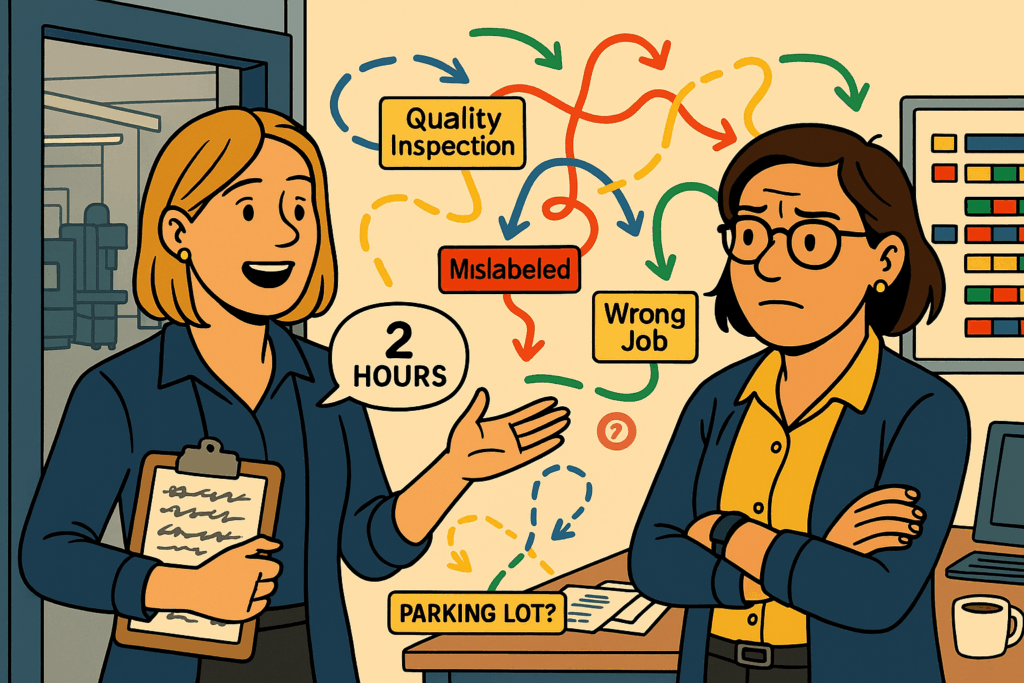

As if summoned to illustrate her point, Jenny appeared at the shop floor entrance, clipboard in hand and the triumphant expression of someone who’d solved a mystery.

“Found the Hoffmann couplings!” she announced. “They were in the quality inspection area, but they’d been moved to make room for the Steinbach components, which weren’t actually the Steinbach components but were mislabeled parts from a completely different job. The actual Steinbach components were sitting at workstation four, where Schmidt had been looking for the Kemper materials, which turned out to be delivered to the wrong receiving dock and were sitting in the parking lot.”

Sarah looked at the phone and her call with Klaus, who had gone silent. She looked at Jenny, whose explanation sounded like something from a sitcom. She looked at the shop floor around her, where a hundred skilled employees were doing their best to manufacture precision components despite working with information systems that would have been inadequate for managing a corner grocery store.

“Jenny,” she said, “how long did it take you to track all that down?”

“About two hours. And I still don’t know where the agricultural component tooling is.

Sarah’s phone buzzed again. Another text from Miguel: “No pressure, but Tom’s really hoping you can make the game.”

A Necessary Commitment

She looked at the message, then at the whiteboard visible through her office window, then at the organized chaos of the shop floor. Somewhere in this maze of confusion were parts for customers who deserved better than mystery-based delivery dates. Somewhere in this system were employees who deserved better than spending their time searching for things that should be findable. And somewhere in this story was a company that had built its reputation on precision manufacturing while tolerating imprecision in everything else.

“Klaus,” she said into the phone, “I need to go to Tom’s football game this afternoon.”

“What?”

“I need to go to my son’s football game. But first, I think we need to schedule a management meeting for tomorrow morning. Because this conversation we’re having right now? We should have had it months ago.”

After hanging up, Sarah stood in the middle of the shop floor for another moment, watching the controlled chaos around her with new eyes. The employees weren’t the problem. The machines weren’t the problem. The customers weren’t the problem. The problem was that they were trying to run a modern manufacturing operation with management systems designed for a much simpler world.

Otto appeared at her elbow as if materialized from thin air. “Figure out where everything is?” he asked with the kind of gentle irony that suggested he already knew the answer.

“Otto,” she said, “what would you say if I told you that in two hours of searching, we managed to locate several missing orders, solve three different material mix-ups, and discover that our receiving department occasionally parks deliveries in the parking lot?”

Otto chuckled. “I’d say that sounds like a pretty typical Monday morning.”

“That’s what I was afraid of.”

The Call from Emma

Sarah looked around the shop floor one more time, then headed back toward her office. She had a football game to attend, a management meeting to schedule, and a growing suspicion that Alpine Precision Components was about to have a very serious conversation about the difference between managing a business and merely surviving one.

The whiteboard in her office still showed the same neat rows of colored strips it had that morning. But now she understood that those strips represented wishful thinking more than actual scheduling. The real question wasn’t how to move the strips around more efficiently. The real question was whether they needed a completely different way of thinking about production management altogether.

Her phone buzzed one more time. Miguel: ” See you at 16:00 so that we can open the cafeteria well in time before kickoff?”

“Absolutely,” she typed back, and for the first time that day, felt confident she could keep a promise.

But as she was gathering her things to check on a few more issues before leaving for Tom’s game, her desk phone rang with the distinctive tone that meant an internal call from the CEO’s office. Emma Weber’s name appeared on the caller ID.

“Sarah, could you please come to my office?” Emma’s voice carried the kind of controlled tension that made Sarah’s stomach clench. “And ask Klaus and Patrick to join us. We need to talk.”

“Is everything alright?”

“I’ve been reviewing our quarterly numbers,” Emma said, and Sarah could hear papers rustling in the background. “We need to have a conversation about what’s happening to our business. How quickly can you get here?”

Sarah looked at her watch, then at the text message from Miguel still glowing on her phone screen. She thought about Tom, probably getting ready for his game, expecting to see her in the stands for once. She thought about the promise she’d just made, the first one today she’d been confident she could keep.

“Emma, I—”

“Sarah, I’m looking at our first negative EBITDA since I founded this company in 1987.” Emma’s voice was quiet but carried the weight of nearly four decades of building a successful business. “Whatever we’re doing isn’t working anymore. We need to figure out what’s broken and fix it, and we need to do it now.”

The line went quiet except for the distant sounds of the shop floor filtering through Sarah’s office window. She could picture Emma in her corner office, probably staring at financial reports that told a story no one wanted to read. A story about a company that had grown from a small machine shop into a successful precision manufacturer, only to stumble when success should have been assured.

“I’ll be right there,” Sarah said finally.

After hanging up, she stared at her phone for a long moment before typing to Miguel: “Emergency meeting called. Will try to make it to the game, but it might be late. Tell Tom I’m sorry.”

She hit send, then immediately felt the familiar weight of disappointing her family settle back on her shoulders. But Emma’s words echoed in her mind: first negative EBITDA since 1987. That wasn’t just a bad quarter—that was the kind of number that threatened everything they’d built together.

As she walked toward Emma’s office, Sarah realized that the chaos she’d witnessed on the shop floor that morning wasn’t just operational confusion. It was a symptom of something deeper, something that was now showing up in the numbers that mattered most. The question she’d been asking herself—what comes next after the whiteboard?—had just become a lot more urgent.

The company that had built its reputation on precision manufacturing was about to have a very precise conversation about survival.